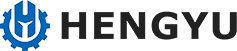

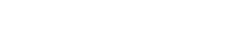

560 Pellet Mill

Keywords:

560 Pellet Mill

Hengyu

Products

About Us

Enterprise strength

Product Overview

Describe:

Biomass pellet mill is a kind of pellet equipment commonly used in the biomass energy industry, which is a new type of fuel molding machinery to replace coal and carbon by crushing biomass raw materials such as tree branches, straw, and pressing them into rod-shaped pellets. Biomass pellet mill is divided into flat die machine and ring die machine, our company produces vertical centrifugal high-efficiency ring die pellet mill combines the advantages of the traditional horizontal ring die and flat die pellet mill, especially suitable for biomass pelletizing.

Specificity:

01Mold flat, direct feeding, material adaptable to a wide range, strong heat dissipation;

02Mould vertical double layer, improve utilization, reduce costs, cost-effective;

03Unique overall design of the spindle, to ensure the concentricity of the equipment, reduce the failure rate of the equipment;

04Automatic intermittent lubrication of the whole machine, prolonging the life of equipment wearing parts.

05The combination of centrifugal force and squeezing force of the pressure roller ensures the molding degree and finish of the pellets and increases the output.

Product Details

Working Principle

Work from the inlet of the material falls vertically in the pressure wheel assembly frame plate on the surface, after the rotation of the frame plate so that the material is continuously distributed in the mold cavity surface (pressure wheel and the mold of the pressing surface), in the pressure roller milling mold holes in the inner surface of the formation of a certain pressure, powdered material into the holes in the inner surface of the mold, the continuous formation of the pile of holes through the mold under pressure (uniformly distributed in the mold on the inner surface of the hole in the effective length of the mold). This process of material by the pressure roller and mold generated by the role of high pressure, high temperature, physical reaction or appropriate chemical reaction (according to the characteristics of the material), to promote the formation of powdered materials continue to lengthen the cylindrical solid body, this cylindrical solid body continues to elongate until the uniform fixed in the frame plate on the toggle knife cut off the knife, forming a certain specification (according to customer requirements to adjust the distance between the knife and the mold's outer surface) of the particles The particles scattered around the mold are concentrated by the toggle knives fixed evenly on the frame plate to the discharge port (shown in the figure), and the particles fall down automatically from the discharge port, and the pellet pressing and molding process is completed.

Main Technical Parameters

|

Model |

Power(kw) |

Capacities(t/h) |

CapacityMold aperture(mm) |

Number ofpressure rolers |

External dimensions(mm) |

|

HY-450 |

55 |

0.8-1.2 |

6-12 |

2 |

1900*1100*1640 |

|

HY-560 |

132 |

1.5-2 |

6-12 |

2 |

2350*1280*1910 |

|

HY-700 |

160 |

2-3 |

6-12 |

2 |

2780*1400*2050 |

|

HY-850 |

250 |

3-4 |

6-12 |

2(3) |

3200*1500*2180 |

|

Note: The above parameters are for reference only, subject to actual conditions. |

|||||

Work Scenario

560 Pellet Mill 04

560 Pellet Mill 03

560 Pellet Mill 02

560 Pellet Mill 01

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.