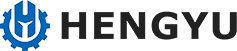

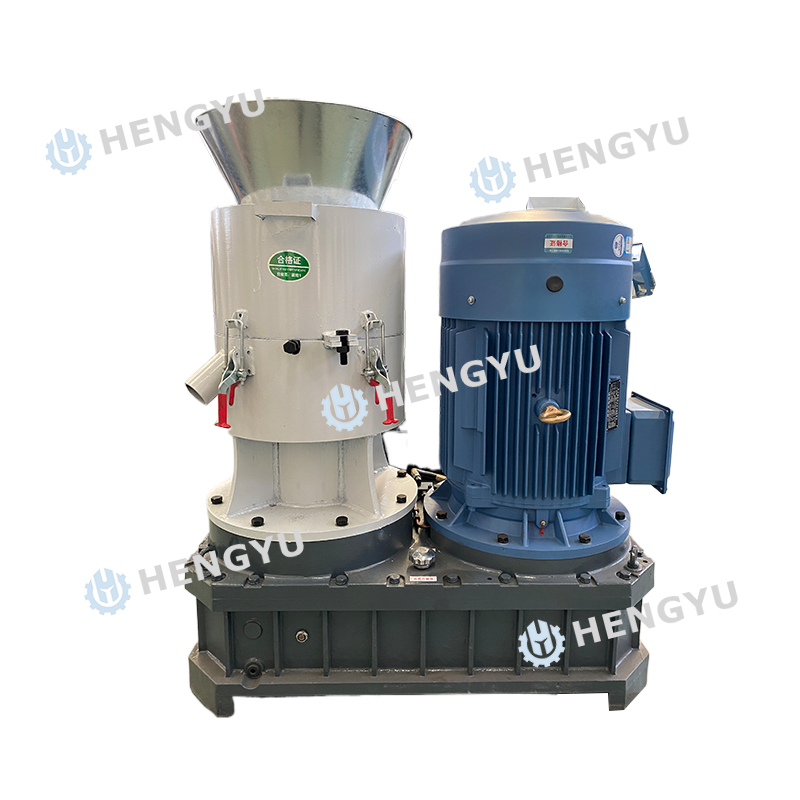

Feed pellet machine

Keywords:

Feed pellet machine

Products

About Us

Enterprise strength

Product Overview

Describe:

Widely used in large, medium and small aquaculture, grain feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plant use

Specificity:

01Dry in and dry out, adopting differential, universal joint transmission, with motor or diesel engine. Low energy consumption, high output, easy to operate;

02Adopting extrusion pelletizing, no need to add water, raw material moisture content between 10%-20% can be pelletized, low energy consumption, high output;

03It can produce concentrate feed pellets, coarse fiber feed pellets, grass meal pellets, which can be suitable for all kinds of poultry: chickens, ducks, geese, etc., all kinds of livestock: rabbits, cows, sheep, pigs, etc., as well as all kinds of aquaculture: fish, shrimp, mussels, loach and other feed production. It can also produce organic fertilizer pellets and compound fertilizer pellets, as well as small production biomass energy pellets;

04Feed production process, the material in the pellet machine die plate, through the friction effect of extrusion molding process, itself produces a high temperature of 50-90 ℃, up to 100 ℃, so that the glucose component of the feed material is converted into a palatable maltose, better stimulate the taste sensation of livestock to enhance the amount of food to improve the digestion and absorption of nutrients. At the same time, it can kill general pathogenic microorganisms and parasites.

Product Details

Working Principle

The raw material falls into the gap between the flat round steel mold and the roller with grooves from top to bottom, is pressed into the mold hole by the rotating roller, and extrudes the long cylindrical shape from the bottom of the mold hole, which is cut off into pellets by the cutter3.

Application Scenarios and Advantages of Feed Pellet Machine

Feed pellet mill is widely used in various scenarios with the following advantages:

High production efficiency: through the efficient extrusion and cutting process, the production efficiency is significantly increased

Low energy consumption: pellet feed is formed under high temperature and high pressure, with lower energy consumption

Environmental protection: avoiding the environmental pollution problem caused by traditional straw burning, helping environmental protection

Main Technical Parameters

| Serial number | Product Model | Input voltage | Power Kw | Overall Dimension(mm) | Overall Dimension(mm) | Production rate kg/h |

Total weight Kg |

| 1 | 150 Normal (2 rolls) | 220V | 4.5KW-4 | 820×310×750 | 80-120 | 46 | 76 |

| 2 | 150 Normal (2 rolls) | 380V | 4KW-4 | 820×310×750 | 80-120 | 46 | 76 |

| 3 | 160 rear axle version (3 rollers) | 220v | 5kw-4 | 960×330×780 | 90-150 | 58 | 92 |

| 4 | 160 rear axle version (3 rollers) | 380v | 4kw-4 | 960X330×780 | 90-150 | 58 | 92 |

| 5 | 210 Regular (2 rolls) | 380v | 7.5kw-4 | 980×450×940 | 200-300 | 107 | 172 |

| 6 | 260 Regular (3 rolls) | 380v | 15kw-4 | 1220×530X1190 | 500-700 | 162 | 279 |

| 7 | 260 Regular (3 rolls) | 380v | 15kw-4 | 1360×470×1210 | 500-700 | 158 | 275 |

| 8 | 300 regular (3 rolls) | 380v | 22kw-4 | 1300×560×1240 | 800-1200 | 197 | 380 |

| 9 | 300 rear axle model (3 rollers) | 380v | 22kw-4 | 1500×530X1310 | 800-1200 | 243 | 409 |

| 10 | 400 rear axle version (4 rollers) | 380v | 37kw-4 | 1740×680×1770 | 900-1300 | 479 | 765 |

Work Scenario

Feed pellet machine 03

Feed pellet machine 02

Feed pellet machine 01

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.