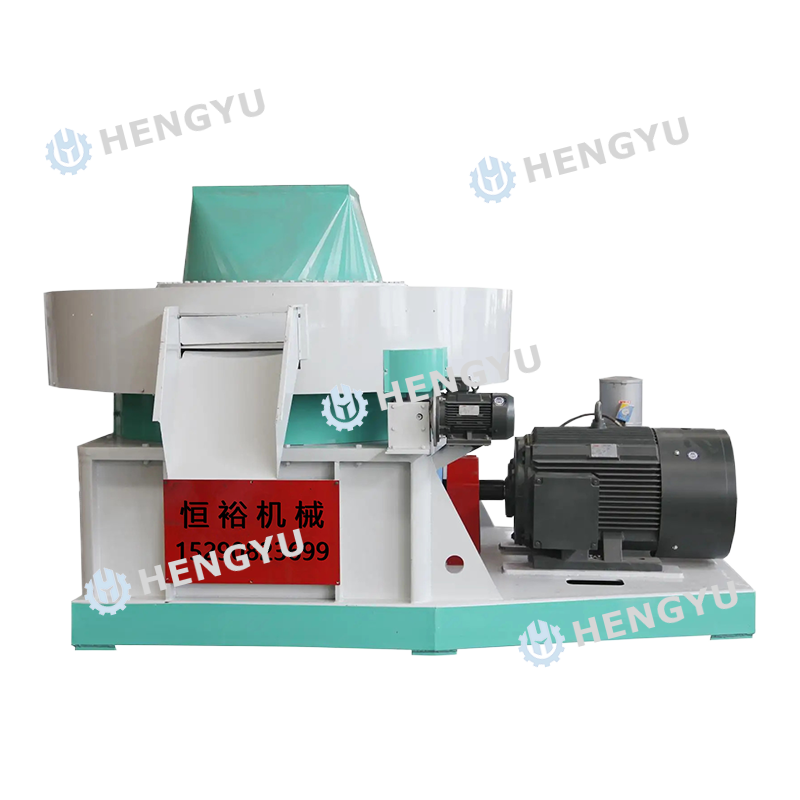

Briquetting machine

Keywords:

Briquetting machine

Products

About Us

Enterprise strength

Product Overview

Describe:

According to the raw material can be divided into biomass briquetting machine and RDF solid waste briquetting machine biomass briquetting machine is to agricultural and forestry waste: straw, twigs, pasture, wood chips, rice husk and other biomass raw materials, will be extruded into a block of a special equipment.

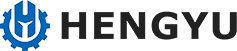

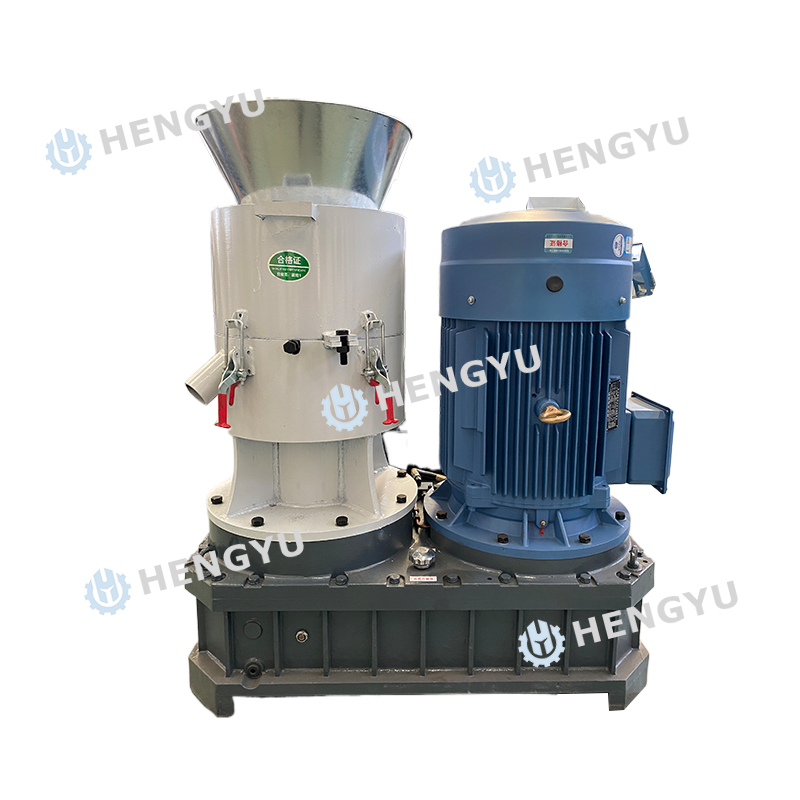

The briquetting machine is composed of frame, motor, feeding port, transmission system, pressure roller, ring mold, electric heating ring, discharge port and other parts.

Biomass curing fuel can be widely used in biological stoves, heating stoves, hot water boilers, steam boilers, drying stoves, biomass gasification stoves, and biomass power plants.

RDF solid waste briquetting machine is mainly used to process all kinds of solid wastes, such as domestic garbage, industrial garbage, agricultural and forestry wastes. Through a series of processing, these wastes are compressed into block fuels with certain shapes and densities for transportation, storage and further utilization. This kind of equipment usually consists of several parts, such as feeding system, compression system, molding system, power system and control system, etc. Each part works in concert to realize the efficient processing and transformation of solid waste.

Specificity:

01Wide adaptability of raw materials: it can adapt to a variety of raw materials, such as crop straw (corn stalks, wheat straw, etc.), forestry waste (sawdust, tree branches, etc.), domestic garbage, industrial garbage, etc. It can be adjusted according to the characteristics of different raw materials to realize high-efficiency briquetting.

02Environmental protection and energy saving: Converting biomass waste into clean solid fuel reduces the dependence on traditional fossil energy and lowers the emission of carbon dioxide and other greenhouse gases. Meanwhile, in the briquetting process, through reasonable design and optimization, it reduces energy consumption and improves energy utilization efficiency.

03High production efficiency: adopting advanced design and manufacturing process, it has high production capacity. Some large biomass briquetting machines can produce several tons or even tens of tons of biomass briquette fuel per hour, which can meet the demand of large-scale production.

04Good quality of briquettes: The biomass briquettes produced have high density and strength, and the general density can reach 0.8 - 1.4g/cm³, which is convenient for storage and transportation. And the shape of the briquette is regular, with good combustion performance, stable flame in the combustion process and even heat release.

05High degree of automation: It is equipped with a perfect automation control system, which can realize the automatic operation of the whole production process, such as feeding, compressing, molding and discharging. The operator only needs to carry out simple parameter setting and equipment monitoring, which reduces manual intervention and improves the stability of production and consistency of product quality.

Product Details

Working Principle

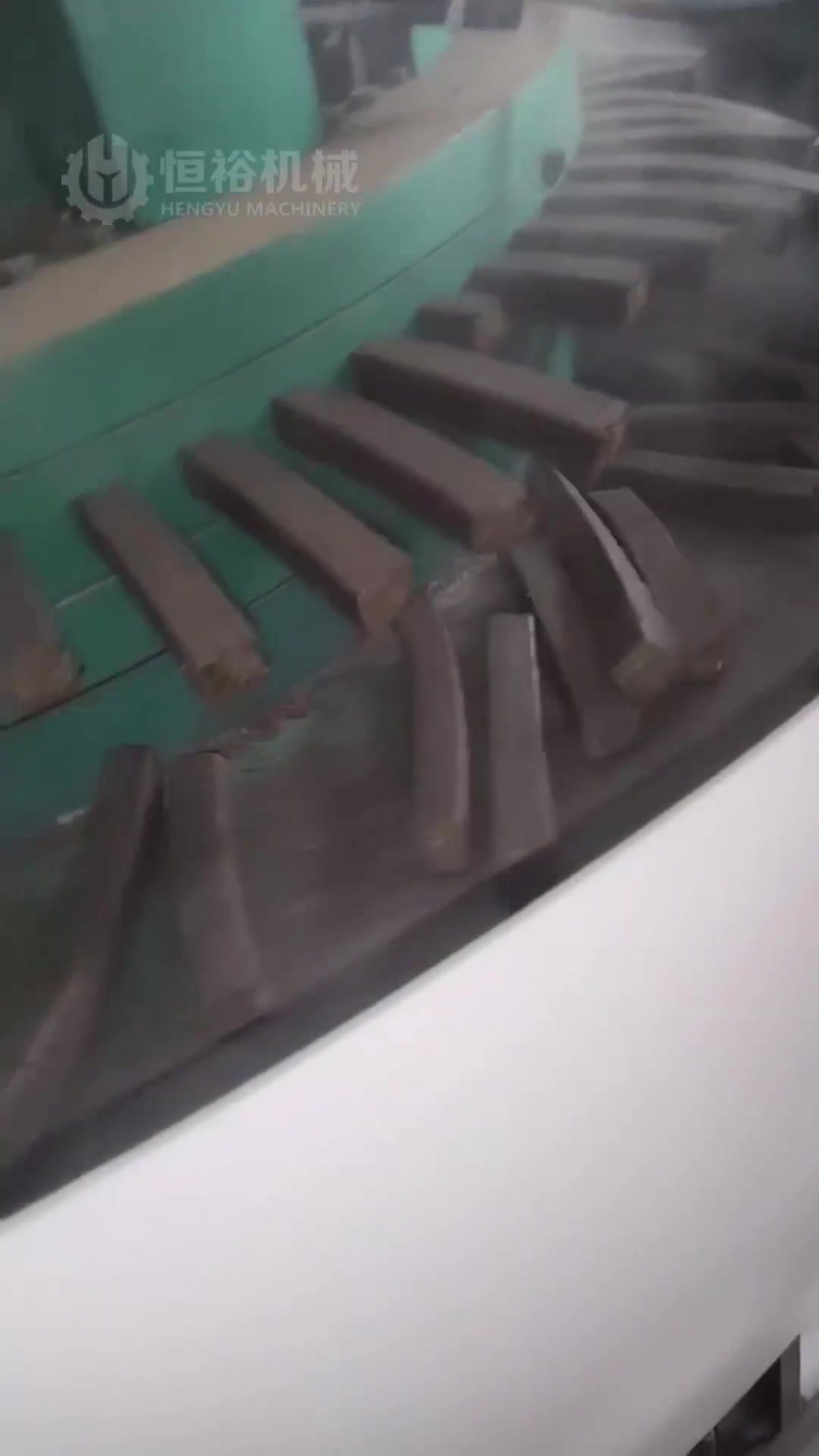

Feeding: The raw materials are transported to the feeding port through the feeding device. The feeding device usually adopts conveyor belt or screw conveyor, which can feed the raw materials into the briquetting machine evenly and continuously. At the feeding port, there is usually a hopper for temporary storage of raw materials to ensure the stability of feeding.Compression: The raw materials entering the briquetting machine firstly go through the pre-compression mechanism, which initially compresses the raw materials, discharges the air in the raw materials, and initially forms a certain shape and density. Then, the pre-compressed raw materials are transported to the main compression mechanism, which further compresses the raw materials through strong pressure. The main pressing mechanism is usually powered by a hydraulic cylinder or a mechanical transmission device, which exerts pressure on the raw material through a press head or a mold, so that the density of the raw material is continuously increased.Molding: Under the action of the main pressure mechanism, the raw material is compressed into a block with a certain shape and size. The shape and size of the molding die is designed according to the product requirements, and the common ones are cylindrical, square and so on. When the raw material is compressed to the set density and size in the mold, the discharging device of the briquetting machine pushes the formed biomass briquette out of the mold to complete the briquetting process. During the whole working process, the control system will precisely control each link according to the set parameters to ensure the stable operation of the briquetting machine and product quality.

Main Technical Parameters

| Model No. | Number of molding holes (pcs) |

Power (kW) |

Capacity (t/h) | Overall dimensions (mm) |

| 9JK-2600 |

52 |

75 |

1-2T/H |

2647×2100×1900mm |

|

9JK-3500 |

72 |

110 |

2-3T/H |

3250×2600×2000mm |

|

9JK-4500 |

88 |

132 |

3-4T/H |

3350×2800×2200mm |

|

9JK-5500 |

100 |

160 |

3.5-4.5T/H |

3000×2300×2000mm |

| Model 9JK-5500 All-in-One 100, 101 holes, 102 holes can be customized |

100/101/102 |

160 |

4-5T/H |

3000×2400×2000mm |

|

9JK-6500 |

120 |

200 |

4-5T/H |

4400×2970×2495mm |

|

9JK-7500 |

136 |

250 |

5-6T/H |

4400×2970×2495mm |

|

9JK-8500 |

176 |

250 |

6-8T/H |

3000×2400×2000mm |

Work Scenario

Integrated Briquetting Machine 02

Integrated Briquetting Machine 01

Briquetting machine 02

Briquetting machine 01

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.