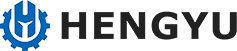

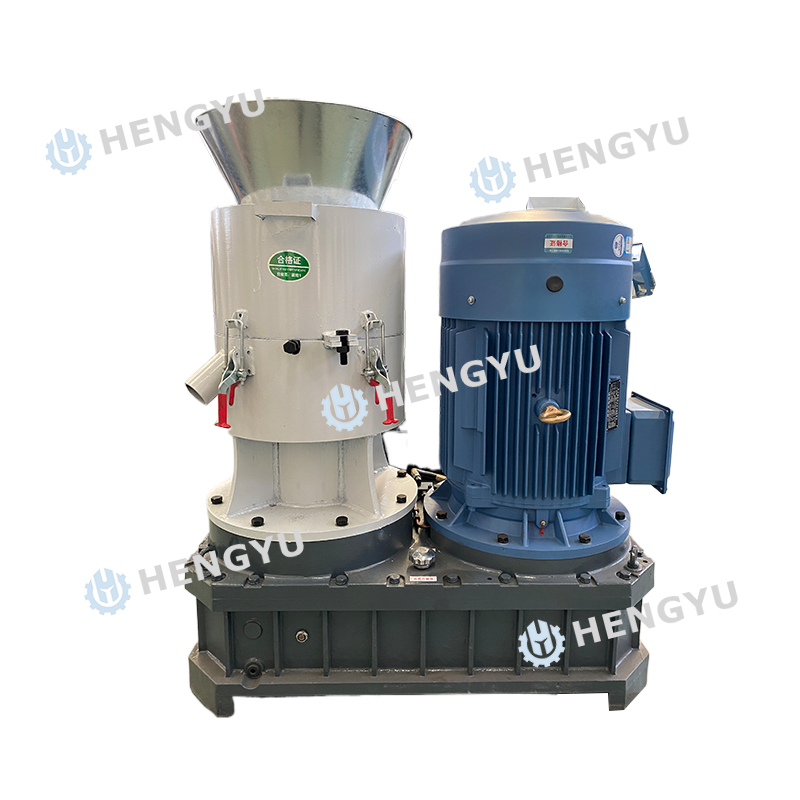

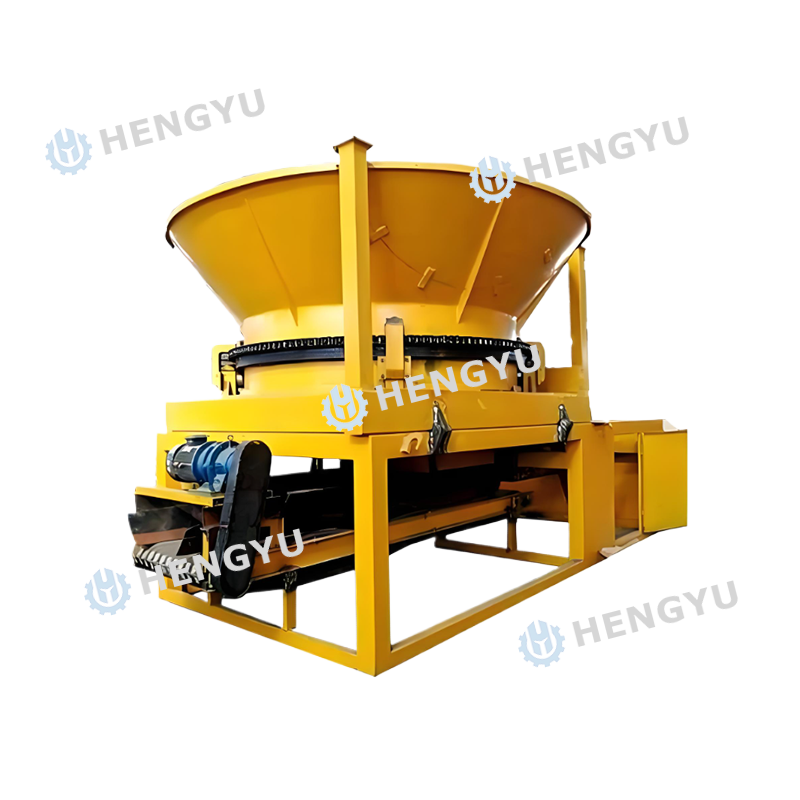

Disc Crusher

Keywords:

Disc Crusher

Products

About Us

Enterprise strength

Product Overview

Describe:

Disc chipper: It is a chipper for producing high-quality wood chips, widely used in paper mills, particle board factories, wood fiberboard factories and other industrial production of the preparation section and a single wood chip production base, the main raw material he cuts is round wood. This machine has the advantages of compact and reasonable structure, easy to operate, high production capacity, good product quality, safe and reliable, easy maintenance. This series of disk chipper adopts low-voltage or high-voltage motor, the feeding is divided into two ways: horizontal feeding and inclined feeding, and the discharging is divided into two ways: upper discharging and lower discharging.

Specificity:

01Efficient cutting: disc chipper can efficiently cut pine, mixed wood, poplar, cedar and other types of logs and bamboo into uniform chips, and the user can flexibly adjust the specification of the discharged chips within a certain range to meet different needs.

02High-quality wood chips: The wood chips cut by this equipment are of uniform length, smooth cut, even thickness, with high qualification rate, and are suitable for paper mills, particle board factories, fiberboard factories and wood chips production bases.

03Compact structure: disc chipper has a compact and reasonable structure, easy operation, large production capacity, low energy consumption per unit of woodchip output, which is the ideal equipment for producing high quality woodchips.

04Wide range of adaptation: the equipment is not only suitable for all kinds of wood, but also can deal with raw materials such as bark, board bark and rotary cut bark, so it has a wide range of adaptation.

05Various feeding methods: the disk chipper has two feeding methods: slanting mouth and flat mouth, and two methods of discharging: upper discharging and lower discharging, which can meet the needs of different users.

06Low energy consumption: disc chipper has low energy consumption per unit of wood chips output, low maintenance cost, convenient feeding and low labor intensity.

Product Details

Working Principle

The working principle of disk chipper is mainly realized by the principle of blade cutting. The disk chipper is mainly composed of blade disk, blade, bearing base, bearing box, bearing, belt, pulley, motor or diesel engine, big shaft, shell and other parts. After starting the motor or diesel engine, the power is transmitted through the belt, which drives the cutter disk on the main shaft and the blades mounted on the cutter disk to rotate repeatedly, so as to carry out the cutting operation.

Working Process.

Feeding and Clamping : Raw materials such as wood and bamboo are put into the feeding opening, which is ensured to remain stable during processing by the clamping device.

Cutting process: With the rotation of the cutter plate and blade, the raw materials are cut into wood or bamboo chips, which flow out from the discharge port.

Chip removal and collection: Waste chips generated during the cutting process are collected and eliminated to a designated location through a chip removal device.

Main Technical Parameters

| Model number | HY2800(1600) | HY3600 |

| Knife roller diameter (mm) | 800 | 800 |

| Knife roller speed (r/min) | 960 | 960 |

| Number of dump knives (pcs) | 6 | 6 |

| Main motor power(KW) | 1400 | 2200 |

| Production capacity (t/h) | 132 | 200 |

| Inlet size(mm) | 10-15 | 30-40 |

| Main machine weight (tons) | 12 | 17 |

| Dimension of main unit(mm) | 7000X4000X4500 | 10000X4000X4500 |

Work Scenario

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.