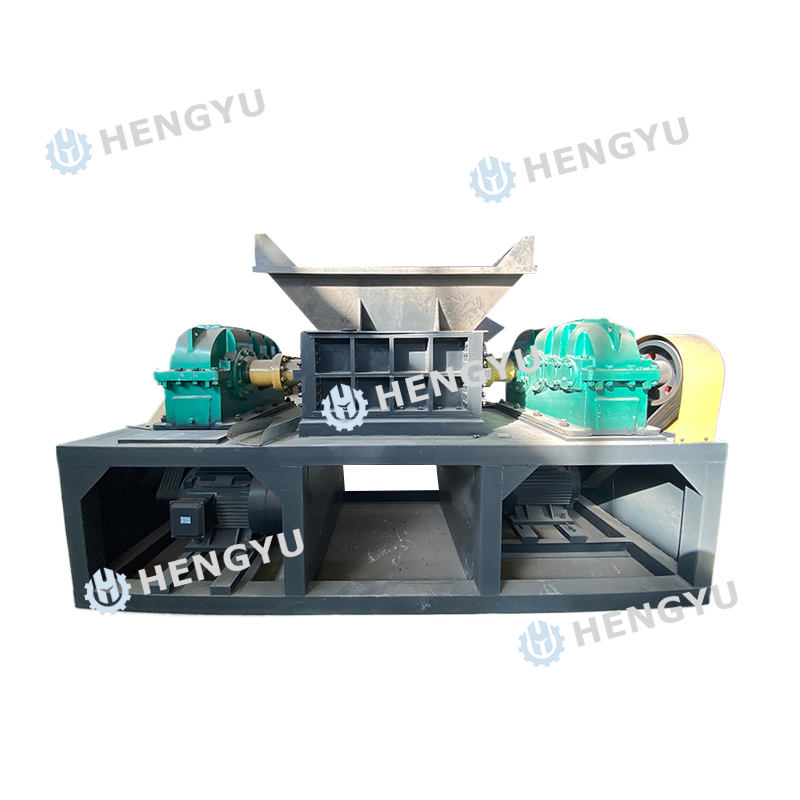

Double Shaft Shredder

Keywords:

Double Shaft Shredder

Products

About Us

Enterprise strength

Product Overview

Describe:

The main function of the twin-shaft shredder is to shred the inconvenient transportation of large materials through the shear of the twin-shaft shredder into materials that meet the requirements. Mainly by the shredding blade set, bearing box, box support, feeding system, power system, electrical control system composed of machines. Suitable for industrial waste recycling, medical recycling, electronics manufacturing, pallet manufacturing, wood processing, domestic waste recycling, plastic recycling, tire recycling, paper and other industry applications. Shredding objects such as all kinds of hollow containers, waste home appliances, waste plastic and rubber products, scrap steel and iron, municipal garbage, domestic garbage, electronic waste, end-of-life vehicles and so on.

Specificity:

01Hexagonal shaft and unique design make it easier to disassemble and replace the tool.

02Low speed, large torque, low noise and less dust.

03Knives are made of 9CrSi, thickness up to 10 centimeters, sturdy and durable.

04The machine frame and plate are made of steel refusing to cut corners, which can resist high torque and is sturdy and durable.

05Microcomputer (PLC) automatic control, start, stop, reverse and overload automatic reverse control function.

06The structure is simple and reasonable, operation and maintenance is more simple.

Product Details

Working Principle

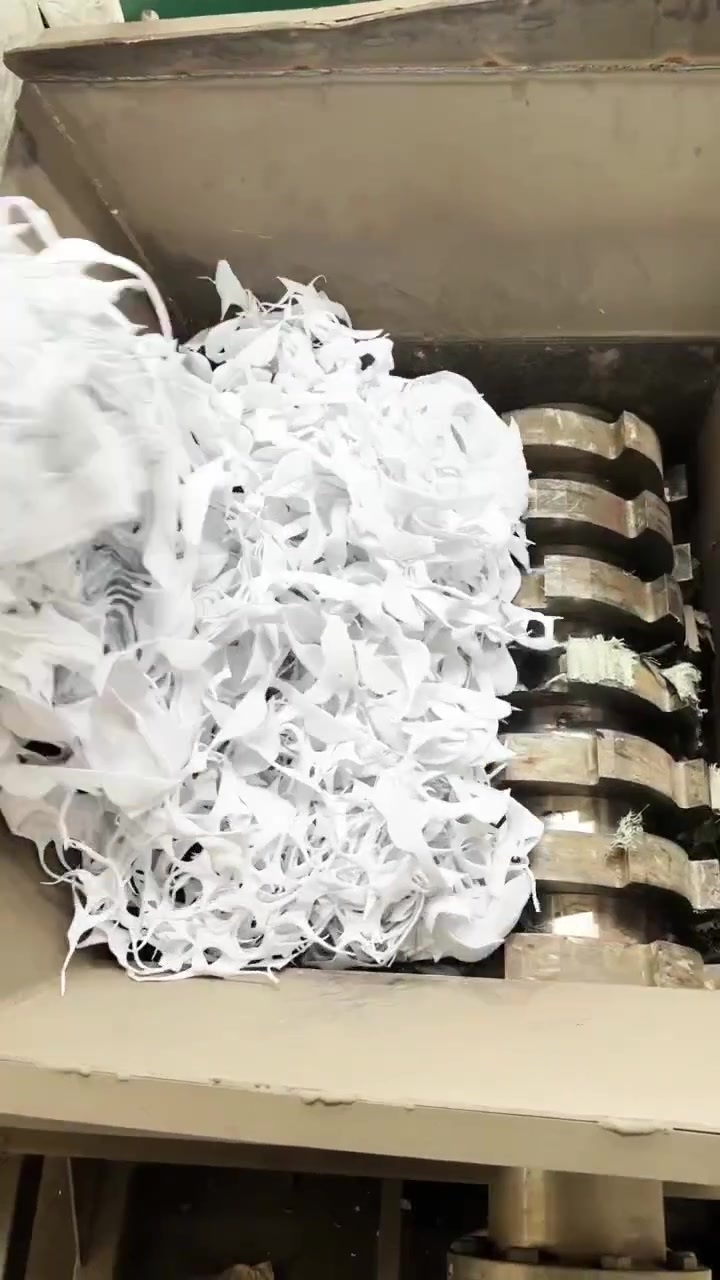

Twin-shaft shredder through the dual motor independently drive two spindles forward and reverse rotation, the spindle on the moving knife bite each other to form a shear, the tip of the moving knife and the knife sleeve cylindrical surface to form a shear, the torque of the spindle and the speed difference between the formation of the tearing so as to achieve the effect of crushing. Due to the mutual biting of the movable knives, the automatic feeding function can be achieved. The unique structure of the knife shaft will not entangle the shaft, or jam the equipment during the production process of low rotational speed and high torque, thus improving the production efficiency.

Main Technical Parameters

| Model No. | Blade | Electrical Machines | Speed Reducer | Capacity (t/h) |

| 600 | Blade φ220mm | Motor 11kw*2 | Reducer 400*2 | 0.4 |

| Blade φ300mm | Motor 15kw*2 | Reducer 400*2 | 0.8-1 | |

| 800 | Blade φ300mm | Motor 22kw*2 | Reducer 500*2 | 1-1.2 |

| Blade φ400mm | Motor 30kw*2 | Reducer 650*2 | 1.5-2 | |

| 1000 | Blade φ300mm | Motor 30kw*2 | Reducer 650*2 | 1.5-2 |

| Blade φ400mm | Motor 37kw*2 | Reducer 750*2 | 2-2.5 | |

| 1200 | Blade φ400mm | motor 45kw*2 | reducer ZSY-315*2 | 2.5-3 |

| Blade φ450mm | motor 55kw*2 | reducer ZSY-355*2 | 3.5-4 | |

| 1600 | Blade φ500mm | motor 75kw*2 | reducer ZSY-450*2 | 6.5-7 |

| Blade φ550mm | motor 75kw*2 | reducer ZSY-450*2 | 7.5-8 |

Work Scenario

Double Shaft Shredder 03

Double Shaft Shredder 02

Double Shaft Shredder 01

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.