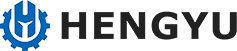

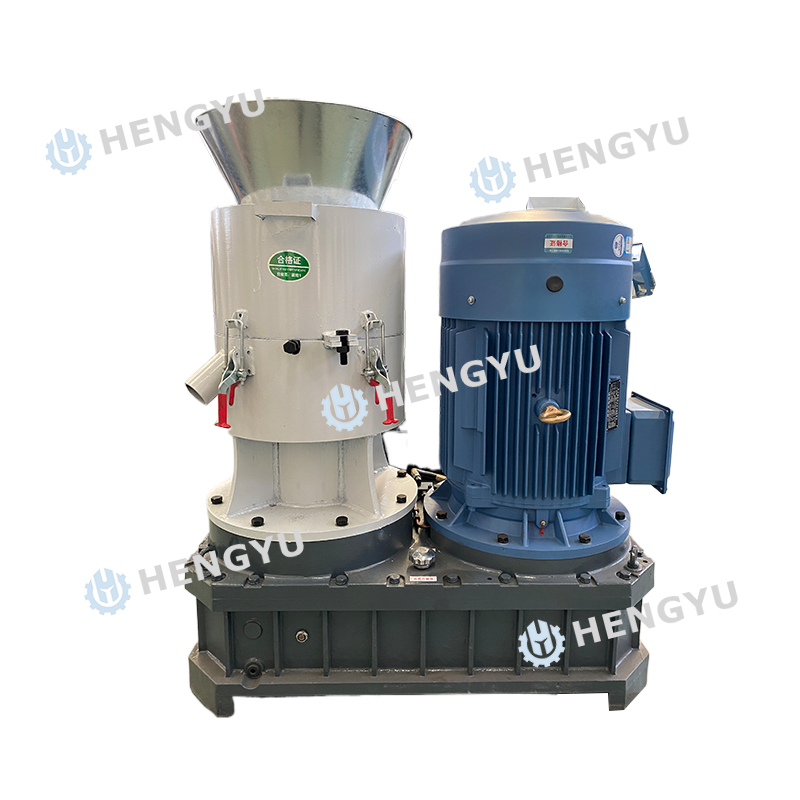

Horizontal Pulveriser

Keywords:

Horizontal Pulveriser

Products

About Us

Enterprise strength

Product Overview

Describe:

Mainly through the interaction between the high-speed rotating blade and stator, the material will be constantly shear, impact and wear. It adopts the principle of “flying knife”, that is, when the blade is rotating at high speed, the sheared material is driven to rotate and form a shear surface at the intersection of the teeth of the stator, which constantly shears, chops and impacts the material, so as to pulverize the material into the required granularity. Horizontal wood crusher can pulverize the raw materials such as timber, tree branches, tree trunks and so on into wood chips or sawdust. Wood chips or sawdust, these materials can be used as raw materials for biomass pellets, used for biomass power generation or as biomass fuel to replace the use of coal, with the advantages of environmental protection and energy saving!

Specificity:

01Large footprint: horizontal pulverizer usually need to be placed horizontally on the ground, so the equipment covers a large area, you need a more spacious site to use;

02High crushing efficiency: horizontal pulverizer is suitable for large quantities of items crushed, with high crushing efficiency, especially suitable for handling larger items;

03Low noise and vibration reduction: horizontal pulverizer with a large diameter and low-speed structure, can effectively reduce noise and vibration, safer operation;

04Flexible feeding: horizontal pulverizer can be fed by self-weight or external forces, suitable for processing larger and denser materials;

05Structural ruggedness: horizontal pulverizer crushing chamber before and after the wall of the double sound insulation design, the machine appearance is beautiful and generous, made of stainless steel materials, durable and easy to clean;

06Versatility: Horizontal pulverizer is not only suitable for crushing large quantities of items, but also can be used for feed processing, forestry waste treatment and other fields.

Product Details

Working Principle

Feeding: The material enters into the cavity of the pulverizer evenly through the feeding port.

Crushing: The motor drives the rotor to rotate at a high speed, the hammer on the rotor under the action of centrifugal force on the material for high-speed impact and shear, so that the material is broken.

Screening: The crushed material is discharged out of the machine through the holes of the sieve plate under the action of its own gravity and airflow. The materials that do not meet the requirements of particle size will remain in the machine and continue to be struck and ground by the hammers until they reach the required particle size.

Discharge: The materials that meet the requirements of particle size are discharged through the sieve plate, and then fall into the collection device by the conveying equipment or directly.

Main Technical Parameters

| Model No. | Model 600 | Model 800 | |

| Number of Hammer Blades | 40 | 60 | |

| Hammer blade material | 60SI2MN | 60SI2MN | |

| Sieve Mesh | Wear-resistant manganese steel | Wear-resistant manganese steel | |

| Motor power | 37 kW (incl. switchgear) | 55 kW | |

| Output granularity | Adjustable | Adjustable | |

| Fan discharge | Integral fan | Independent fan 7.5 kW | |

| Refuse to accept material | Cyclones and Bag Dust Collectors | Cyclone bag filter | |

| Production capacity | About 1 ton | Around 1.5-2 tonnes | |

| Internal structure | Body with wear-resistant liner | Body with wear-resistant liner | |

| Main unit size | 2280*1500*1570(LWH) | 2310*1335*1635(LWH) |

Work Scenario

Horizontal Pulveriser

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.