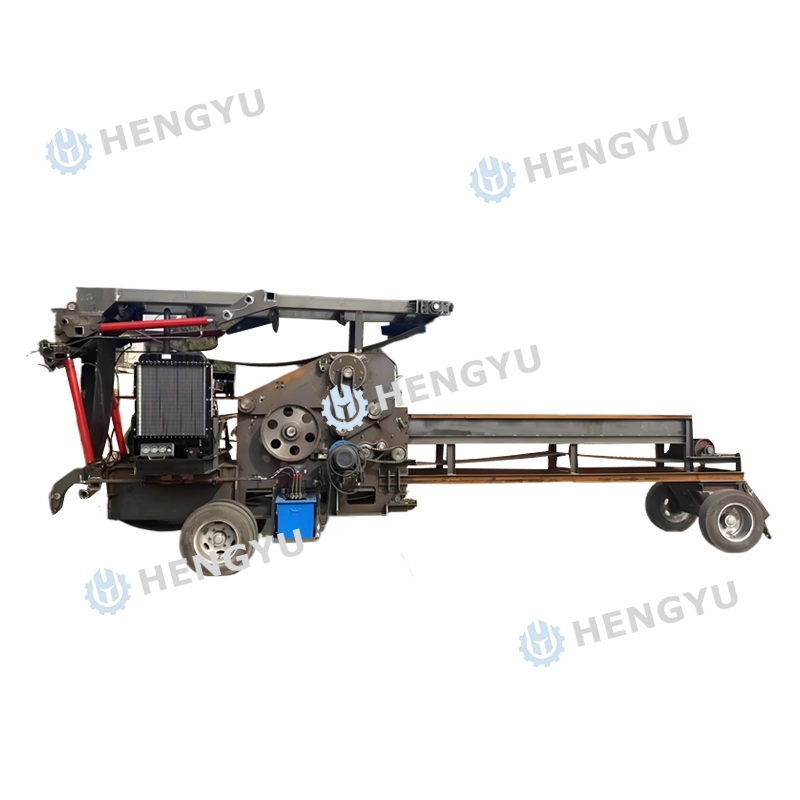

Mobile Traction Crusher

Keywords:

Mobile Traction Crusher

Products

About Us

Enterprise strength

Product Overview

Describe:

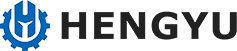

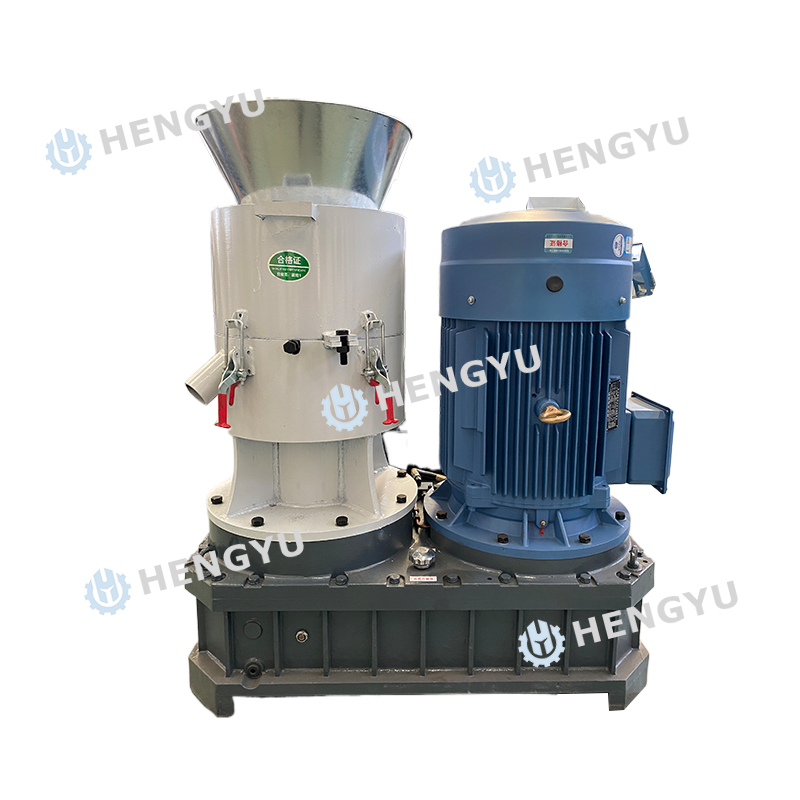

Mobile folding diesel version of the crusher processing raw materials widely, (easy and flexible deployment) can be processed wood such as all kinds of small-diameter wood, veneer, slats, round wood core, building moldings, etc., as well as all kinds of non-wood raw materials such as all kinds of bulk straw, cotton firewood, reeds, etc., a wide range of applications.

Specificity:

01High efficiency and energy saving: the mobile folding plate diesel crusher is driven by diesel engine, which can drive the normal operation of the equipment by diesel power generation in the case of inconvenient electricity, especially suitable for field operation and the ring of insufficient voltage power.

02Strong mobility: the equipment is usually towed by a semi-trailer, which can stop the production at any time and anywhere, and adapt to a variety of narrow and complex working environment. In addition, it can also be quickly transferred to the field, saving valuable time and enhancing operational efficiency.

03Easy to operate: the mobile folding plate diesel crusher is equipped with PLC control system and touch screen display, realizing remote precise control, one-button operation, safety and efficiency.

04Good environmental protection performance: integrated high-efficiency dust collector and atomized spraying system, guaranteeing environmentally friendly operation. Hydraulic drive technology and intelligent control system further enhance the environmental protection and intelligent performance of the equipment.

05Convenient maintenance: the hydraulic system is easy to maintain, only need to regularly check the quality of hydraulic oil and replace the filter element and other routine maintenance work.

06Versatility: The equipment can be configured with different specifications of crushing chambers and knives according to customers' needs, to meet the requirements of different discharge size and output, and is widely used in pulp mills, paper mills, biomass power plants and other fields.

Product Details

Working Principle

Power source: The crusher adopts diesel engine as the power source, and the diesel engine drives the main engine through the belt pulley deceleration drive. The power of the diesel engine is transmitted to the host wheel through the belt, which in turn drives the various parts of the crusher to work. Feeding system: The wood is transported to the pressure roller through the chain plate, and the pressure roller squeezes and crushes the wood. The crushed wood then passes through the hammer head and other striking operations in the crushing chamber, and finally flows out from the small wood discharge conveyor. In addition, the wood is put onto the chain plate intelligent conveying feeding table through the claw machine, and enters into the crushing chamber after extruding and crushing by the hydraulic feeding rollers.

Crushing and cutting: Blades and hammer blades are installed inside the crushing chamber for cutting and hitting the wood. After transporting, crushing and cutting, the wood flows out from the bottom discharge conveyor, or the discharge conveyor can be installed in the discharge part to facilitate direct loading and transportation.

Control system: The control system of the crusher includes hydraulic system and electrical system. The hydraulic system converts mechanical energy into hydraulic energy through hydraulic pump, controls the flow and pressure of hydraulic oil, and realizes various actions and functions of the system. The electrical system, on the other hand, is responsible for monitoring and controlling the operation status of the whole equipment.

The features of folding mobile diesel version crusher include:

High-efficiency crushing: with the design of high-strength blades and hammer blades, it is able to quickly crush wood into fine particles and improve the processing efficiency.

Energy saving and environmental protection: compared with the traditional electric power drive, diesel power has lower energy consumption and emissions, while dust and noise are effectively controlled, in line with environmental requirements.

Convenient to move: compact design, reasonable structure, easy to transport and move, applicable to a variety of site requirements.

Multifunctionality: it can be adapted to various narrow and complex working environments, with the functions of feeding, crushing, screening and transportation.

Main Technical Parameters

| Model No. |

Power (output) |

Production capacities |

Inlet size |

Applicable material diameter |

Rotor Diameter |

Number of moving knives (pieces) |

|

HY-216 |

55 |

3-5 |

600 |

≤200 |

650 |

3 |

|

HY-217 |

90 |

4-6 |

700 |

≤250 |

650 |

3 |

|

HY-218 |

110 |

6-8 |

800 |

≤350 |

800 |

6 |

|

HY-1000 |

110 |

8-10 |

1000 |

≤200 |

650 |

6 |

|

HY-1300 |

132-160 |

10-15 |

1300 |

≤350 |

800 |

6 |

|

HY-1400 |

160-200 |

15-20 |

1400 |

≤400 |

800(1050) |

6 |

|

HY-1600 |

220-250 |

18-25 |

1600 |

≤350 |

800(1050) |

6 |

|

HY-2000 |

250-315 |

25-30 |

2000 |

≤350 |

800(1050) |

6 |

Work Scenario

Mobile Traction Crusher 02

Mobile Traction Crusher 01

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.