Straight-through dryers

Keywords:

Straight-through dryers

Products

About Us

Enterprise strength

Product Overview

Describe:

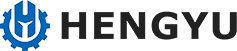

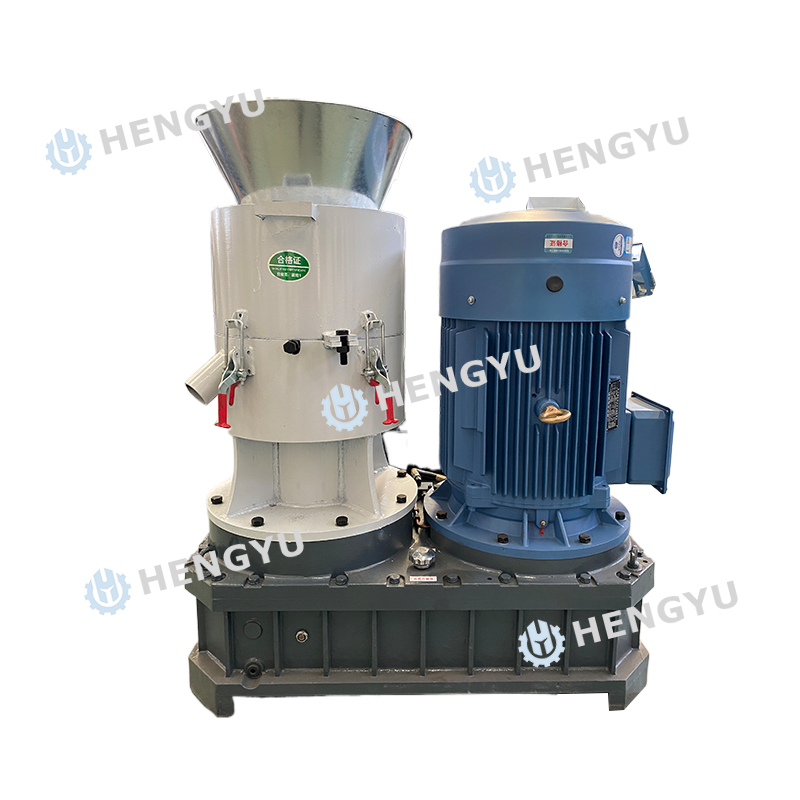

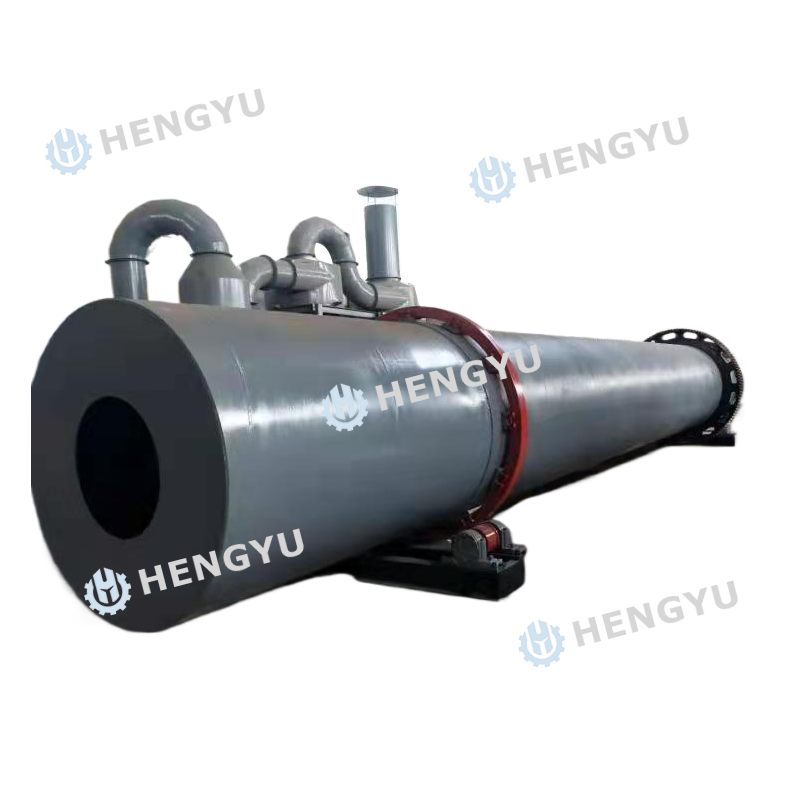

Straight cylinder dryer is a kind of continuous drying equipment widely used in industry, mainly for removing water or other volatile components from materials. Its core structure is a horizontal or slightly inclined cylindrical cylinder, which realizes efficient drying through rotation and hot air. Commonly used in mineral, chemical, building materials, agriculture (such as grain drying) and food processing industries, applicable to granular, powdery or lumpy materials.

Specificity:

01High efficiency and energy saving: the straight dryer adopts hot air circulation mode, which effectively improves the utilization rate of heat energy and reduces energy consumption;

02Uniform drying: through the turning effect of the internal coping structure, it ensures that the materials can be evenly heated and improves the drying quality;

03Wide applicability: straight dryer can be applied to a variety of materials drying needs, with strong versatility;

04Easy to maintain: the structure of the equipment is simple and clear, easy to daily maintenance and repair;

05To summarize, with its high efficiency and energy saving, uniform drying and other characteristics, straight dryer has been widely used in many industries. Through in-depth understanding of its working principle, we can better grasp the operation and maintenance of this equipment, to provide a strong guarantee for the drying part of the production process.

Product Details

Working Principle

Material Putting: The materials to be dried are evenly put into the straight dryer through the feeding port. 2. Hot Air Circulation: The hot air produced by the hot air oven is sent into the dryer by the action of fan to exchange heat with the materials.

Hot air circulation: The hot air produced by the hot air furnace is sent into the dryer to exchange heat with the materials under the action of the fan. At the same time, part of the hot and humid air will be discharged through the humidity discharge port to keep the humidity balance inside the dryer.

Material turning: In the process of drying, the coping structure inside the dryer will keep turning the material to ensure that the material can be heated evenly, to avoid the phenomenon of local overheating or over-wetting.

Completion of drying: When the material reaches the required degree of drying, it will be discharged through the discharge port to complete the whole drying process.

Main Technical Parameters

| Specification/Model |

Power (output) |

Number of revolutions per minute |

Drying capacity |

Fan power |

|

Φ325mm(Pulsed air flow) |

- |

- |

0.5-1 |

11 |

|

Φ800*10m(Straight tube) |

5.5 |

1-6 |

1 |

11 |

|

φ1000*10m(Straight tube) |

5.5 |

1-6 |

1-1.5 |

15 |

|

φ1200*16m(Stromatolite) |

7.5 |

1-6 |

2-3 |

22 |

|

φ1500*16m(Stromatolite) |

11 |

1-6 |

3-4 |

30 |

|

φ1600*16m(Stromatolite) |

11 |

1-6 |

4-6 |

37 |

|

φ1800*18m(Stromatolite) |

15 |

1-6 |

6-8 |

45 |

|

φ2100*20m(Stromatolite) |

18.5 |

1-6 |

7-9 |

55 |

|

φ2600*24m(Stromatolite) |

30 |

1-6 |

8-10 |

90 |

|

φ2800*28m(Straight tube) |

37 |

1-6 |

8-10 |

110 |

|

Φ3000*30m(Straight tube) |

45 |

1-6 |

10-15 |

110 |

Note: The moisture content of raw materials is ≤40%, and the drying capacity changes with different moisture of raw materials. The above parameters are for reference only, please refer to the actual.

Work Scenario

Straight-through dryers

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.