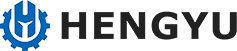

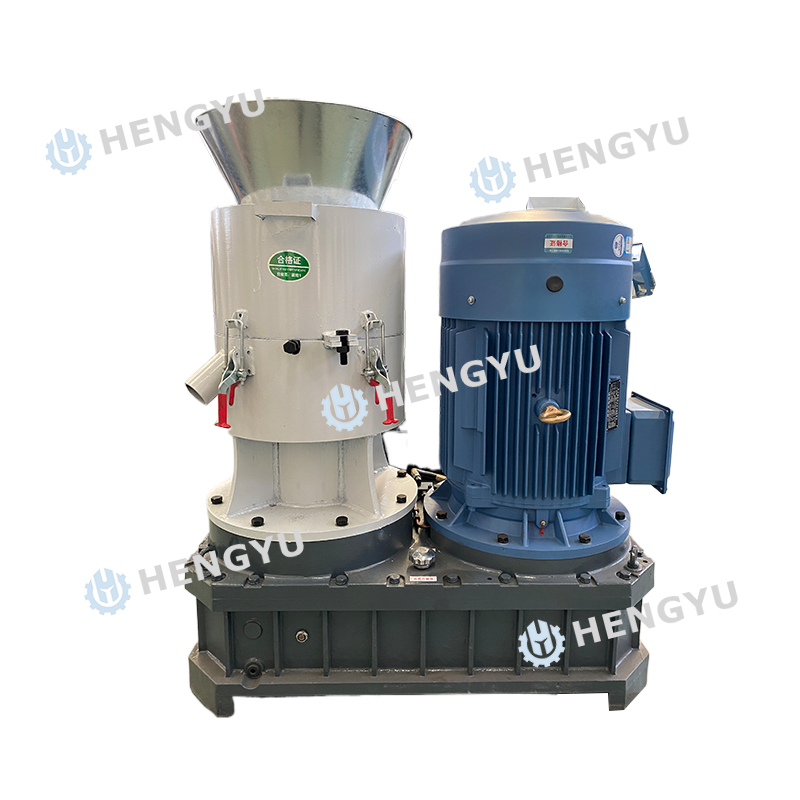

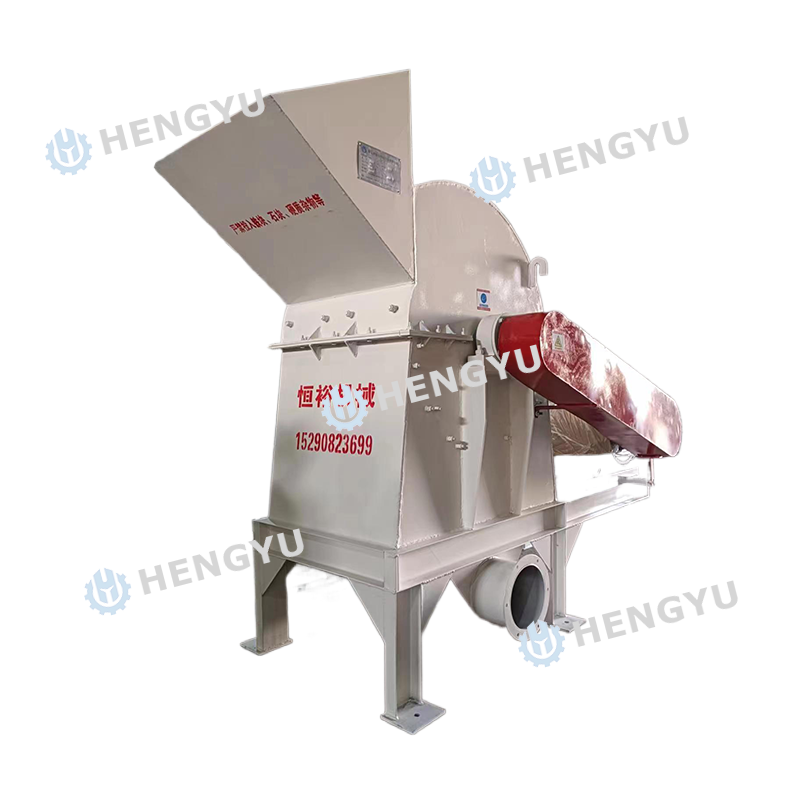

Vertical Pulveriser

Keywords:

Vertical Pulveriser

Products

About Us

Enterprise strength

Product Overview

Describe:

It is a kind of fine crushing equipment without sieve bar and adjustable type, which is widely used in the final crushing of various materials, especially in the compound fertilizer industry, where it is most commonly used. Its design is based on domestic and foreign advanced fine crushing equipment, with simple structure, low operating costs, high crushing rate, energy saving and so on.

Specificity:

01Simple structure, easy to operate: the structure of the vertical mill is designed to be simple, easy to maintain and operate the equipment. The working principle of the equipment is also more intuitive, users get started faster and more efficient.

02Higher output: the vertical mill has a high rotational speed, which can achieve high crushing efficiency, especially suitable for mass production. Its high-speed rotor can quickly pulverize the raw materials, suitable for high efficiency crushing.

03Strong adaptability, applicable to a variety of materials: the vertical mill is applicable to a wide range of raw materials, such as livestock and poultry manure, straw, food waste and so on. This makes the equipment in the production of organic fertilizer can deal with a variety of different organic materials.

04Small footprint: the design of the vertical mill makes it have a small footprint, suitable for space-limited production sites.

05Lower energy consumption: compared with some traditional crushing equipment, the vertical mill has lower energy consumption. Its efficient rotation system and reasonable crushing process can reduce energy consumption to a greater extent, improve production efficiency.

06Strong equipment stability: due to the vertical structure design, the equipment in the work of better stability, less vibration, and reduce the chances of material clogging.

07Low maintenance costs: the parts of the vertical mill is more wear-resistant, and equipment maintenance and replacement cycle is longer, reducing the maintenance costs and downtime of equipment.

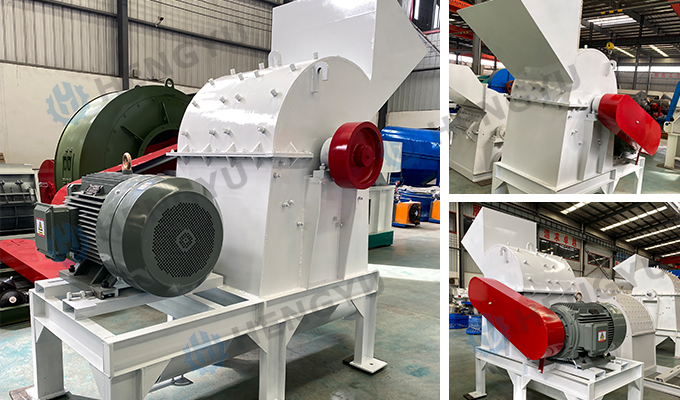

Product Details

Working Principle

Feeding: The material enters the pulverizer from the feeding port.

Impact and crushing: in the shell, the material and the high-speed rotation of the knife or hammer head collision, through the impact, extrusion and crushing.

Repeated crushing: the material is continuously subjected to the action of knives in the crushing chamber, until the particle size is smaller than the aperture of the screen.

Discharge: smaller particles in the centrifugal force through the screen discharge, while the larger particles continue to stay in the crushing chamber is repeatedly crushed.

Vertical pulverizer has the characteristics of simple structure, low running cost, high crushing rate, energy saving, etc. It is suitable for crushing many kinds of materials, especially widely used in compound fertilizer industry and mineral processing equipment.

Main Technical Parameters

| Model No. | Power (kW) |

Rotation speed (r/min) |

Production capacity (t/h) |

Number of Hammer Blades (pieces) |

| HY800 |

55/75 |

2100 | 1-2 | 60 |

| HY1000 | 90 | 2100 | 2-3 | 60 |

Work Scenario

Vertical Pulveriser 02

Vertical Pulveriser 01

Send Inquiry

Leave a message immediately and receive free product consultation. We will arrange experts to contact you as soon as possible.